If you need to order a custom wheel, it helps to be familiar with some common industry wheel terminology. Below is a summary of key terminologies and meanings from the wheel dictionary and the importance of each.

For historical reasons wheels are measured in inches. When discussing a wheel size, it is common to state the rim width followed by the rim diameter. It is also possible for fractions of an inch to be used. For example:

Commonly the rim size will be stamped on the rim.

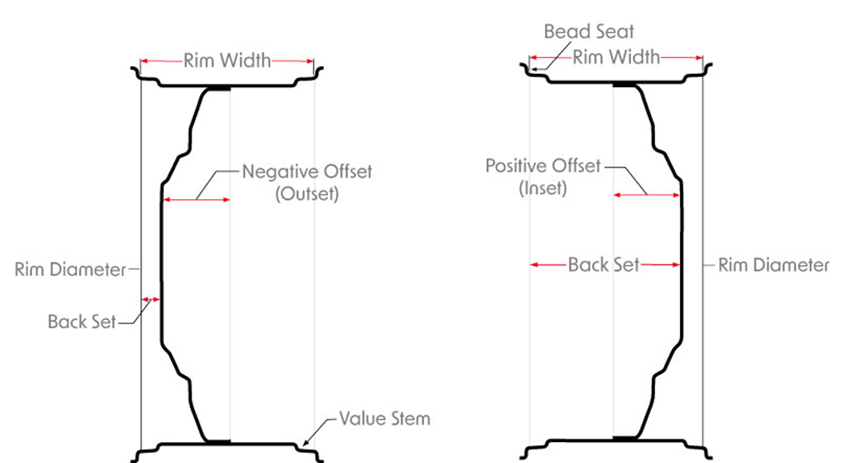

Rim Width

The width of a rim (or wheel) measured between the bead seats.

Rim Diameter

The diameter of a wheel as measured from the bottom of the bead seat.

Bead Seat

The surface where the tyre and wheel form a sealing seat when assembled.

Back Set (Backspace)

A measurement from the mounting face to the rim’s bead seat.

Negative Offset (outset)

When a wheel’s hub mounting surface (center) is behind the wheel centerline, or toward the center of the machine.

Positive Offset (inset)

When a wheel’s hub mounting surface (center) is in front of the wheel centerline, or toward the outside of the machine.

Drop Center

The inside diameter of the rim at the point where the center disc is normally welded into the rim.

Valve Guard

Often a welded cover on the wheel to protect the valve stem.

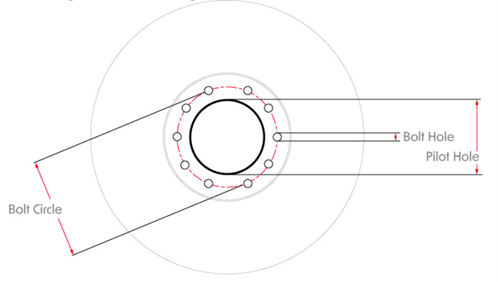

Bolt Pattern

A wheel’s mounting pattern, which includes 4 pieces of information:

Pilot Hole

The centre bore is the diameter of the hole in the centre of the wheel. Pilot may also be referred to as ‘Centre bore’.

Bolt Circle or Pitch Circle Diameter (PCD)

The distance between bolt holes on opposing sides of the wheel (center of hole to center of hole). For example, you would measure from the center of the 12 o’clock hole to the center of the 6 o’clock hole.

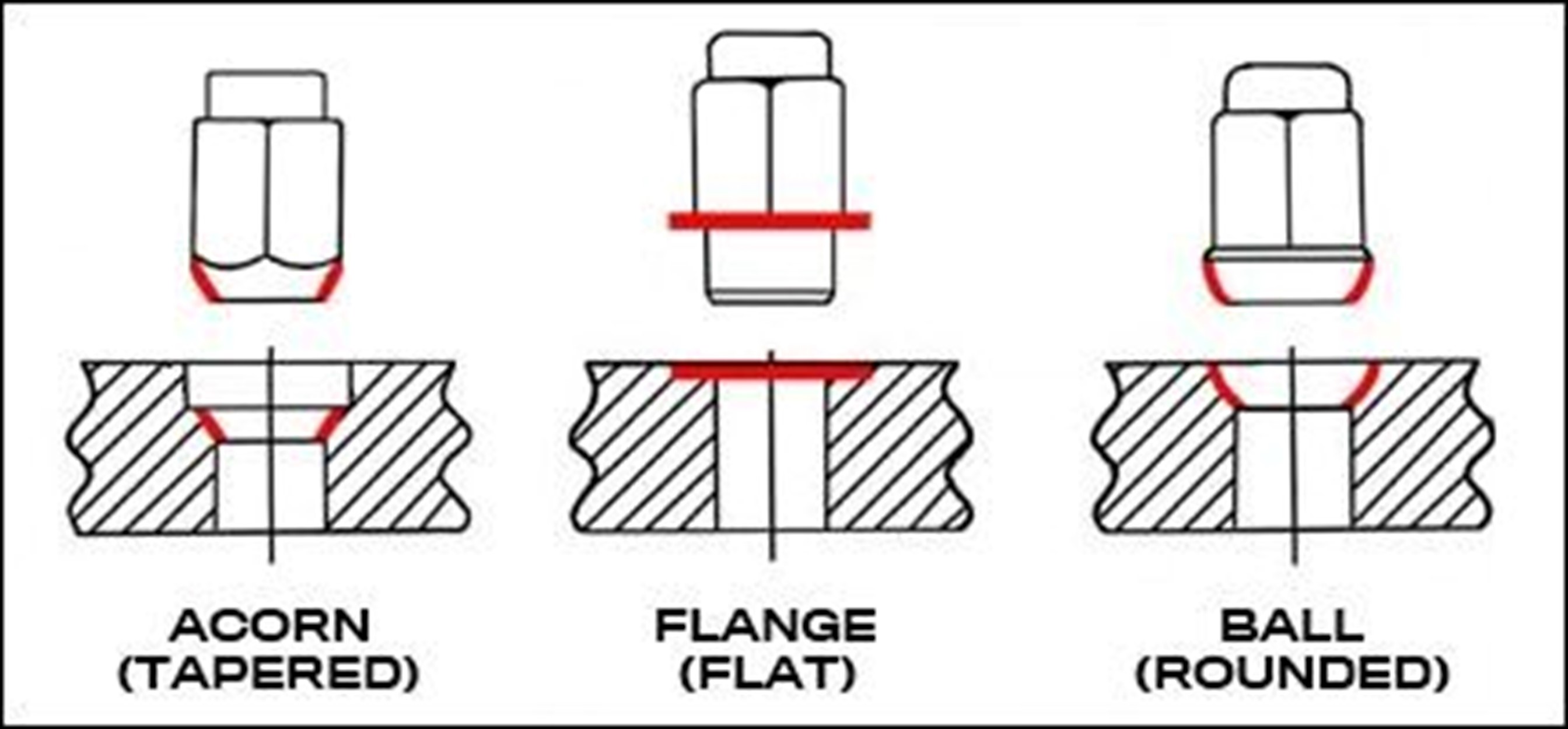

Stud hole diameter and Type

Stud hole diameter is self-explanatory - it is the diameter of the hole. Type refers to the shape of the hole and there are three main types:

If you’re measuring up a wheel for your own machine or a customer’s machine and you have a question about what you need to measure, or how you should measure it, call TRS Tyre & Wheel and one of our experts are ready to help.